Sugar Motor Research Page

Sugar Motor Formulas

I have cast Dextrose and Sorbitol

grains. My current favorite is Sorbitol. It melts at a lower

temperature, but more important to me is it has better working and

casting properties. The sorbitol casts in a manner more similar to my

PBAN with rolled logs mostly not sticking too much until packed. A

couple raps on the table will slide the log to the bottom of the

casting tube. I found Dextrose to be extremely sticky to work with and

difficult to cast in 54mm tubes (with mandrel).

Candy Motor

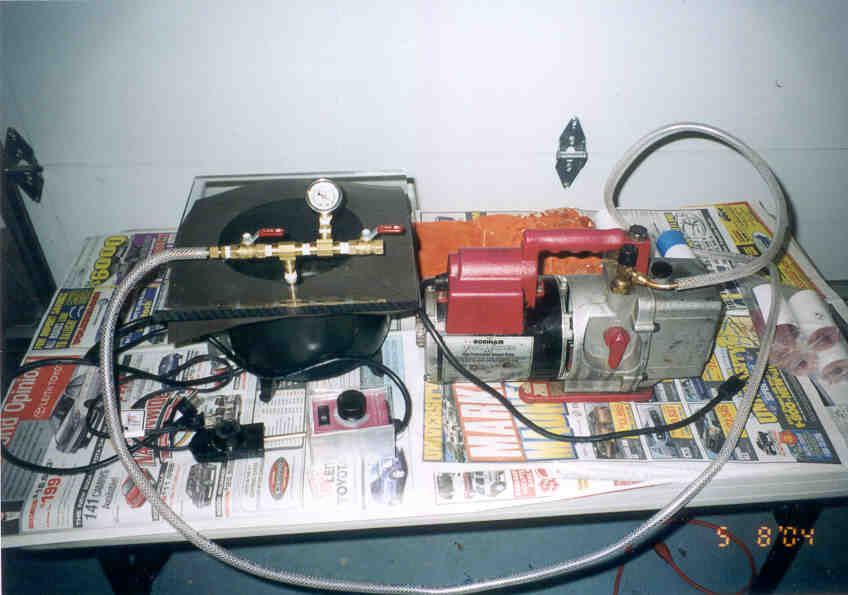

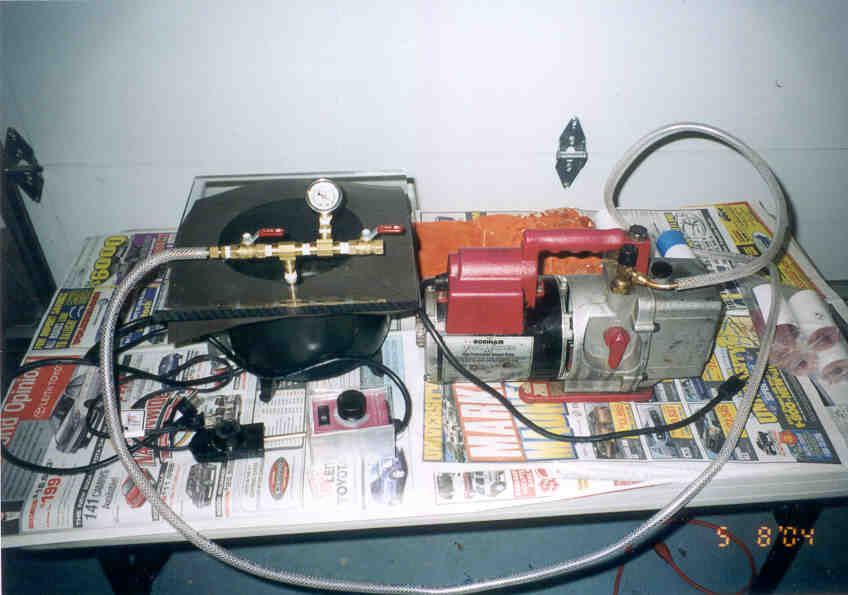

Workbench - KNSB, KNDX

I use a Waring Kitchen Kettle to melt directly with no oil or wax bath.

I do use a Router speed controller set at low to minimize local hot

spots by lowering the on-temp of the heating elements. Do be extremely careful if you don't use a

double boiler or wax bath! In particular thin pots can be very

problematic.

Vacuum Processing

I find improved grain density and

quality by vacuum processing. My Candy Motor Workbench picture

illustrates my complete setup, but I do have a

Vacuum Processing page with

additional detail on the vacuum processing system and on that page will

maintain any improvements I make.

Casting

I use Loki casting bases and mandrels

and Lyngdal liners.

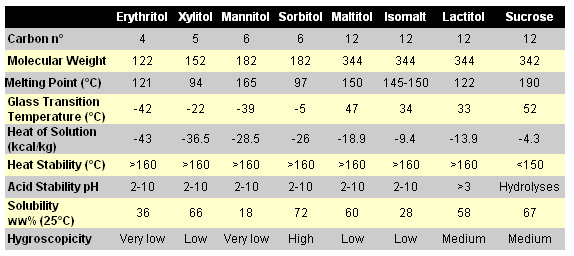

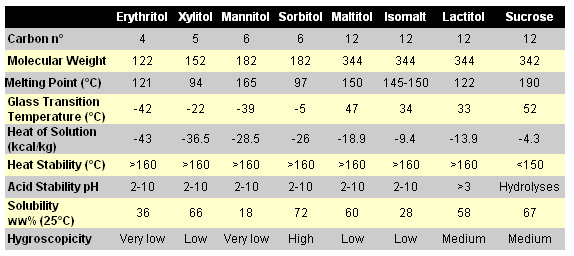

Sugars

Sucrose, Dextrose, and Soribitol are

all common. I prefer Sorbitol as it's casting propertites are far

superior to the others. In particular it's the least sticky to handle

and it's melting temperature is also the lowest of the 3

Jimmy and a few others like to add or substitute some Karo to

facilitate processing.

Formulas

Basic

65% KNO3

35% Sorbitol

Sparky

Generally metal additions should be

about +10%

58.2% KNO3

31.3% Sorbitol

0.1% Graphite

10% Titanium Flake

Properties

Click on table to visit table source web page.

Candy Motor Links